The WASTX Plastic

The WASTX Plastic

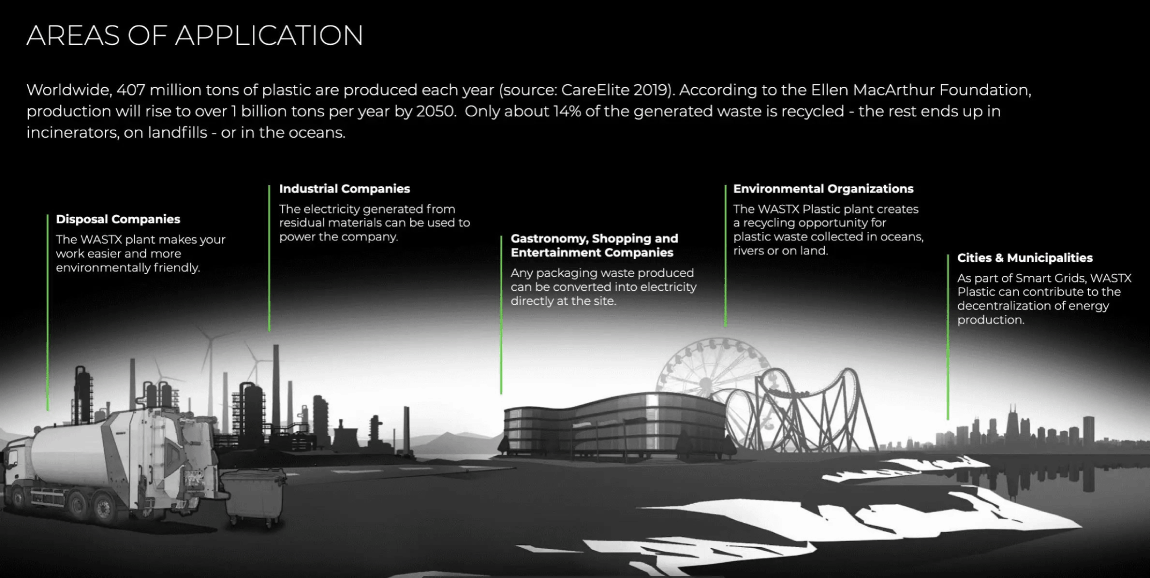

The environmental solution to end-of-life plastics

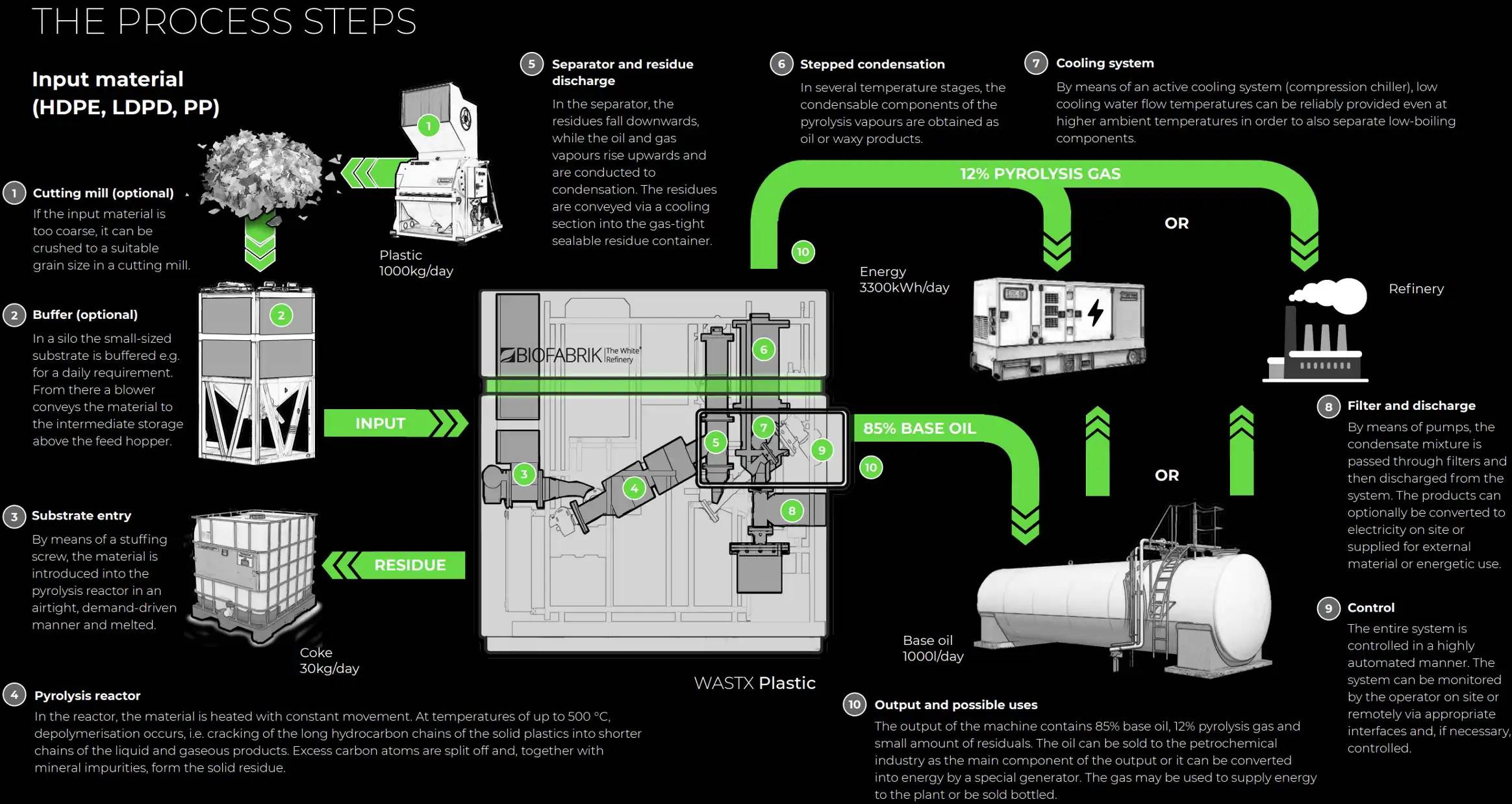

The WASTX Plastic plant converts plastic waste and selected organic materials into energy. It is characterized by a modular, decentralized and scalable design. The technology can be viewed as an orderable series system.

How Does It work ?

-

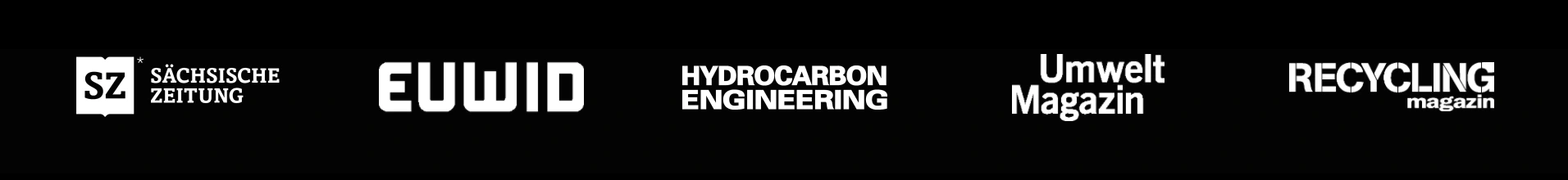

1 kg of plastic converts to 1 litre of Fuel: The plant processes post-consumer waste materials such as HDPE, LDPE and PP into a high-quality energy source with a fuel value of 11 kWh.

-

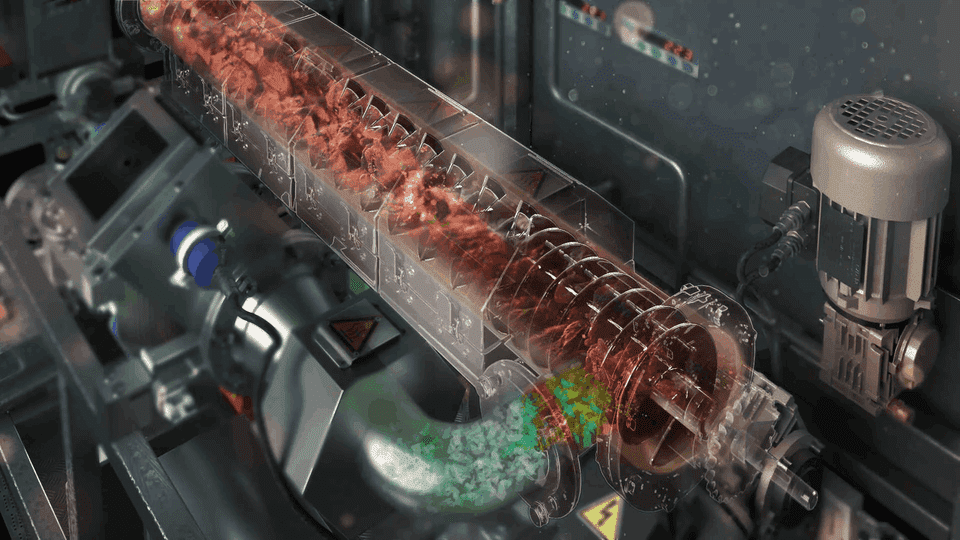

Fully automated Reactor: The input substrate is disintegrated in a single process, distilled and converted into fuel or, if required, into electricity.

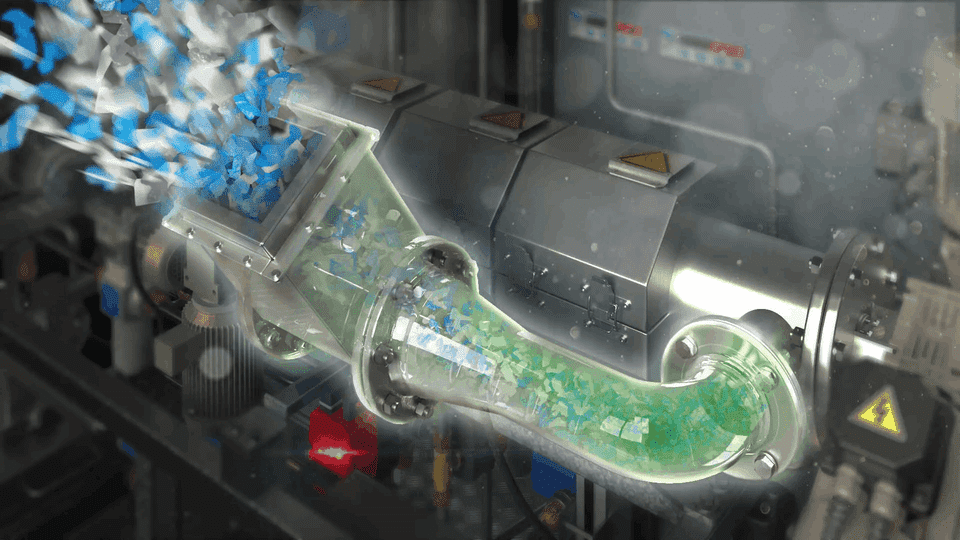

Plastic waste becomes a valuable raw material

- The tasks in plastics recycling are as varied as the nature of the different raw materials.

- WASTX Plastic is the first container-based, decentralised plant from the Biofabrik to process plastic waste or production residues that cannot be directly recycled into materials or energy-recyclable oils and waxes.

THE KEY FACTS

The WASTX Plastic converts post-consumer plastic waste into synthetic crude oil (Syncrude) and energy-rich gas. It is characterized by a modular, decentralized and scalable design.

- Converts 1 kg of Plastic to 1 l of Syncrude

- Fully Automated Reactor

- Only 0.5 kWh per Litre

- Decentralized Container Design

- Shredder and Substrate Silo

- Use of Electricity and Heat

The processes in plastic recycling are as varied as the nature of the different raw materials. WASTX Plastic is the first container-based, decentralised plant from Biofabrik to process plastic waste or production residues that cannot be directly recycled into materials or energy-recyclable oils and waxes.

WASTX Plastic

Scalable due to Parallel connection

- The plants are consistently installed in containers and are suitable both for the expansion of existing recycling plants, and for the fast, space-saving and uncomplicated installation of a complete WASTX system.

- Optionally the WASTX Plastic can be delivered in a 40ft container. One entry periphery can supply up to 3 modules